Cartridges@kemela

Cartridges need to be matched to the tonearm they will be fitted in as they vary in weight; the tonearm counter weight needs to be appropriate, and the compliance (flexibility/elasticity of the cantilever suspension) needs to be suitable for the effective mass of the tonearm so record warps don't overly "bounce" the cartridge.

The height of the tonearm and the height of the cartridge should allow the dust cover to close (if there is one) and facilitate the vertical tracking angle.

The phono stage needs to be suitable for the cartridge's output and electrical parameters.

So quiet a few things to consider even before "alignment"

Moving Coil v Moving Magnet

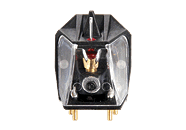

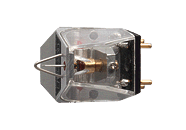

Moving Magnet (MM) designs have higher outputs and thus less gain is needed from the phono stage. Bass response and R/L channel separation can be good, but the mechanics of moving a higher mass (magnets are attached to the shank and the cartridge body houses the coils) limits high frequency tracing and decreases the threshold for mistracking. They are physically a bit more robust and some brands offer replacement styli without having replace the whole cartridge - or realign it.

Moving Coil (MC) cartridges are more delicate. They have a lower effective tip mass and a thinner shank with coils moving adjacent to magnetics that are now in the body of the cartridge. Moving Coil (MC) cartridges trace higher frequencies more easily because with a lower moving mass, the response time is faster due to lower inertia. There are also other aspects of generator linearity and magnetic flux effects benefiting performance. Performance may drift more than moving magnet cartridges if critical suspension elements change their physical characteristics over time. They require a more elaborate - and therefore more expensive - phono stage for low noise and good dynamic range. A high performing tonearm and table is required to achieve the sonic potential of a moving coil cartridge and upgrading to this kind of platform is a significant step up in investment in vinyl record playback that only a dedicated vinyl enthusiast will want to entertain.

Alignment/setup

A cartridge may be rotatable in X,Y and Z axes and axially (further in or out in the head shell - if there is one and it has slots) and vertically translatable (up and down). Sound quality will be more affected when a cartridge is lesss than optimally aligned especially with more elaborate stylii profiles. Mistracking of the more heavily modulated passages, particularly towards the end of the side, is likely to mean both a misaligned and worn stylus. When groove wall damage occurs over a large section of the groove wall, permanent loss of information results. You can install and reasonably set up a cartridge with a few basic tools but some cartridges are far more forgiving than others and some tonearms offer more adjustment than others. However all alignments are a compromise and the thickness, and cutting tool used in the production of a record vary from record to record.

Cartridge settings

While most manufacturers provide the tracking weight range, bias compensation is not usually specified (and actually the amount required varies across the record!!)

Price points

The diamond tip is a big cost factor in the price of a cartridge. Less expensive ones use bonded styli - a smaller cap of diamond glued onto a stub. More expensive cartridges use whole "nude" diamonds that can be machined into the more complex geometries that provide the broader groove contact area. The hardness quality and degree of polish is also a factor. Stronger magnetic materials are also desirable but there is a cost to be paid. Hand assembly is required and there is yield loss from cartridges which don't meet specs and have to be reworked or discarded.

How long do they last?

Hard shellac 78 rpm records would wear out crude inexpensive steel styli after a small number of plays. Today's laser cut diamond styli last a lot long longer and depending on the geometry and degree of fine polishing a stylus will typically last for between 1000 to 2000 record plays. When a cartridge is correctly aligned the gradual loss of high frequencies as the stylus ages is more likely due to a worn stylus than a worn groove. Poorly aligned cartridges however will 'mistrack' greatly accelerating both stylus and record wear. If significant groove wear has occurred, changing to a stylus with a broader area of contact may recover high frequencies from a section of the groove wall that has not been worn.